Precision Engineering, Global Compliance, Unmatched Capacity

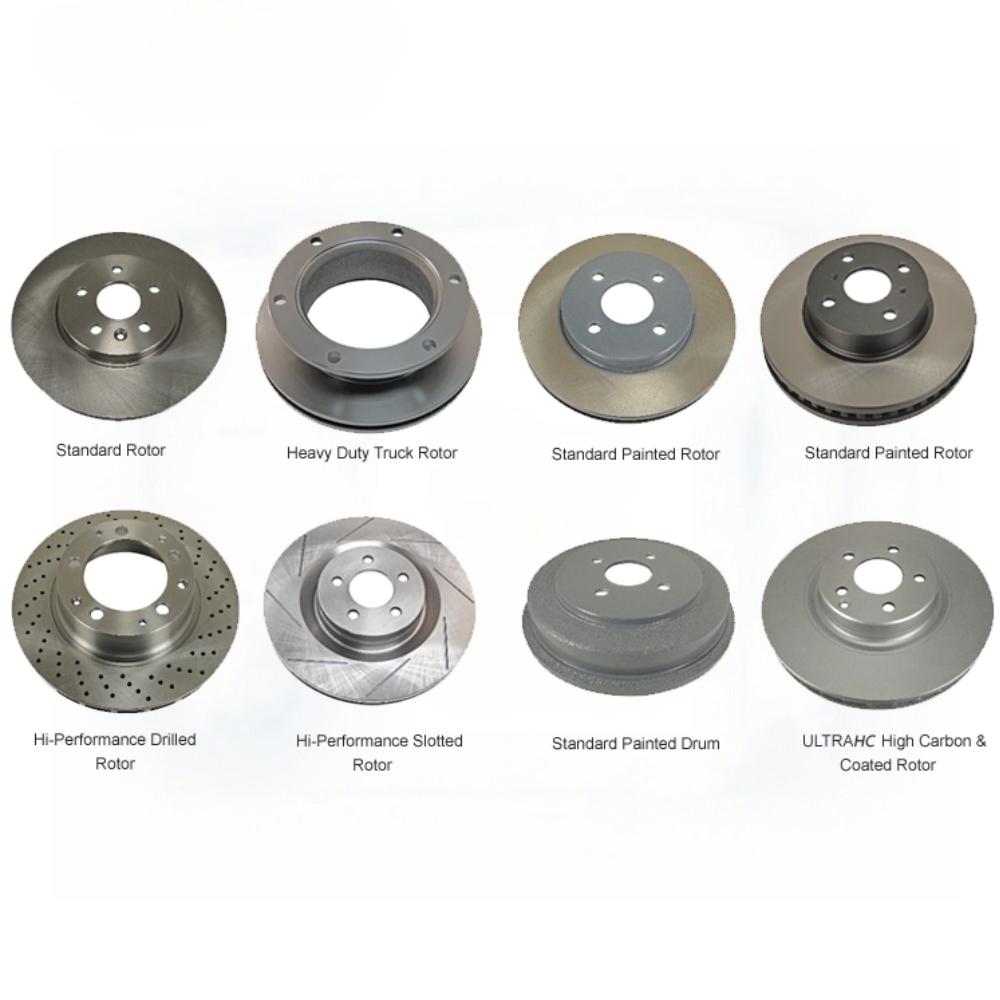

Specializing in producing high-performance brake discs that meet rigorous global standards. With state-of-the-art facilities and a commitment to quality, we serve OEMs and aftermarkets worldwide.

Production Capabilities

- Advanced Manufacturing Infrastructure

2 x 2T/H Induction Melting Furnaces: Ensure consistent material purity and alloy composition.

17 CNC Machining Lines: Guarantee micron-level precision (±0.02mm tolerance).

Annual Output: 3 million units, scalable to meet bulk orders.

- Comprehensive Quality Control

Material Testing Lab:

Spectrometer (ISO 17025 compliant) for G3000-grade gray iron verification.

Metallographic microscope, tensile testing machine, and Rockwell hardness tester,etc.

Dynamic Balancing Machines: Achieve <10g·cm imbalance (exceeds ISO 1940 G6.3).

End-of-Line Inspection: 100% dimensional, runout, and surface finish checks.

Certifications & Compliance

- IATF 16949: Automotive quality management system certified.

- E-Mark (ECE R90): Compliant with EU braking system regulations.

- COP (Certificate of Conformity): Validated for OEM specifications.